As well as the material itself, NANESA offers a line of graphene-based composite semi-finished products developed for direct integration into industrial applications. These semi-finished products combine graphene with polymer matrices or other materials, ensuring superior performance in terms of lightness, strength and conductivity.

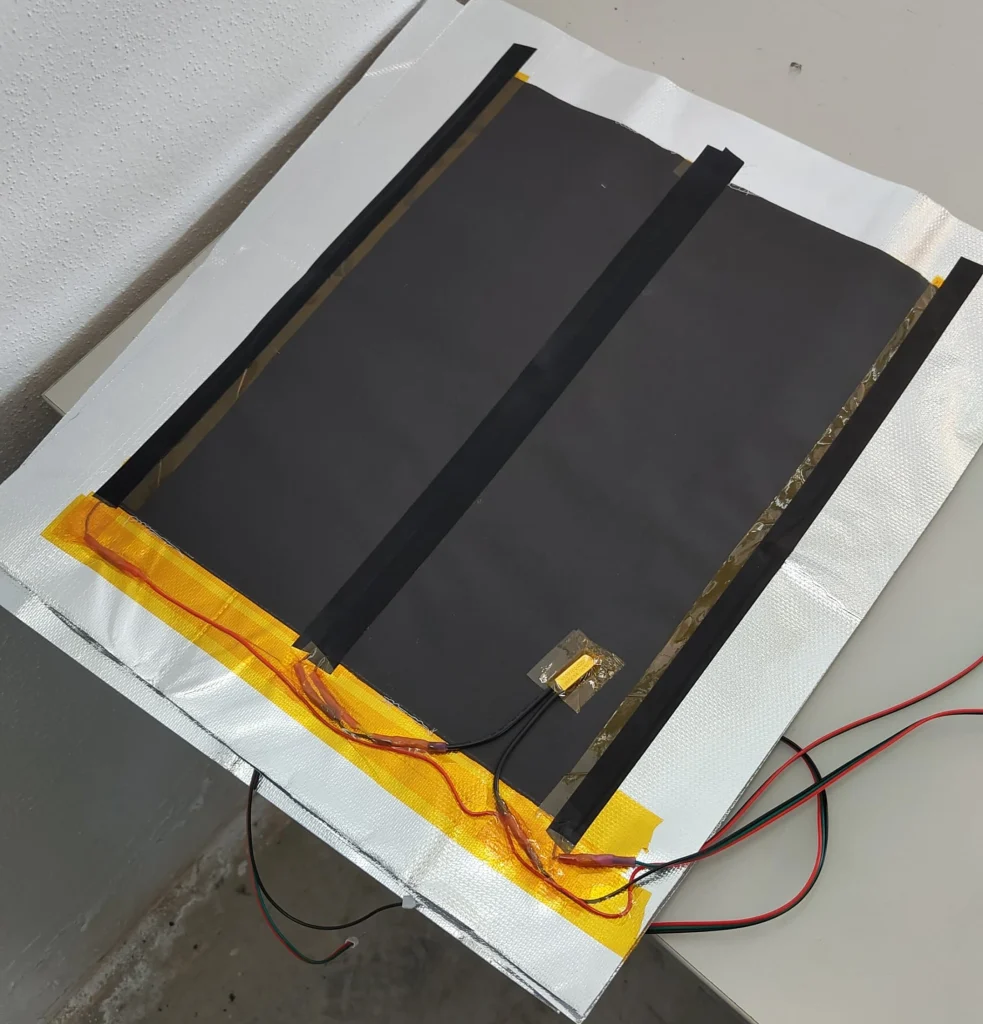

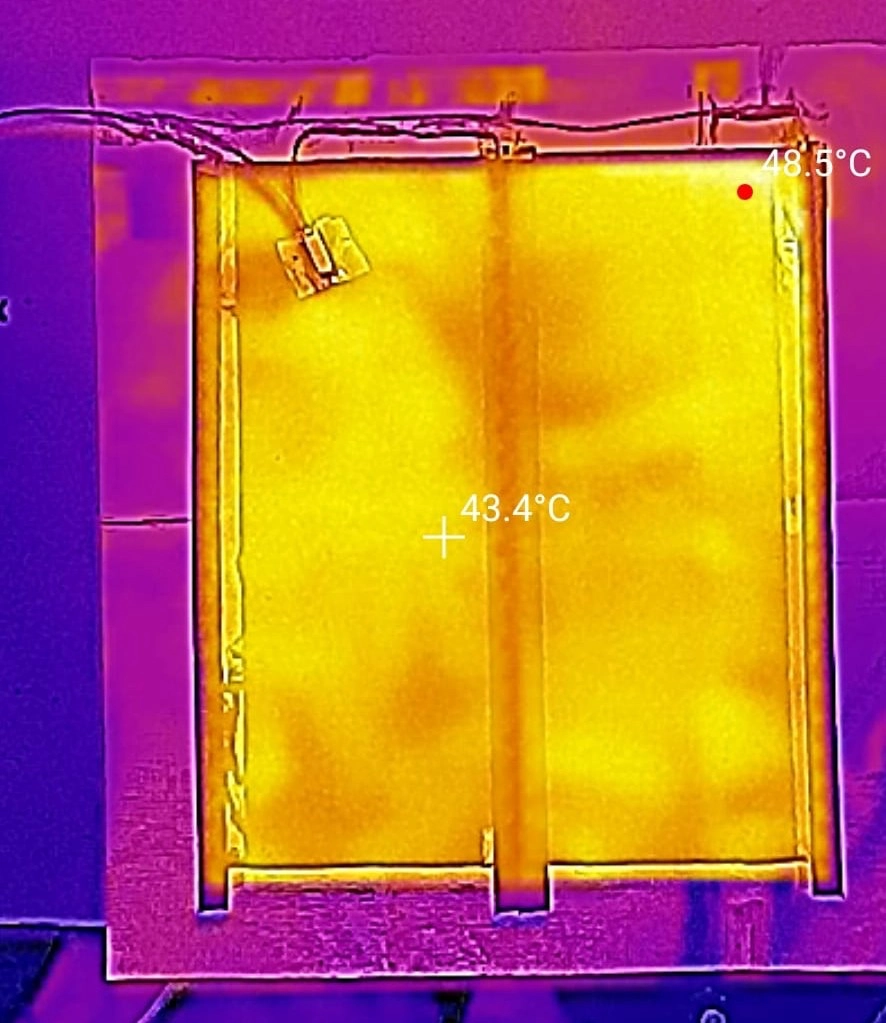

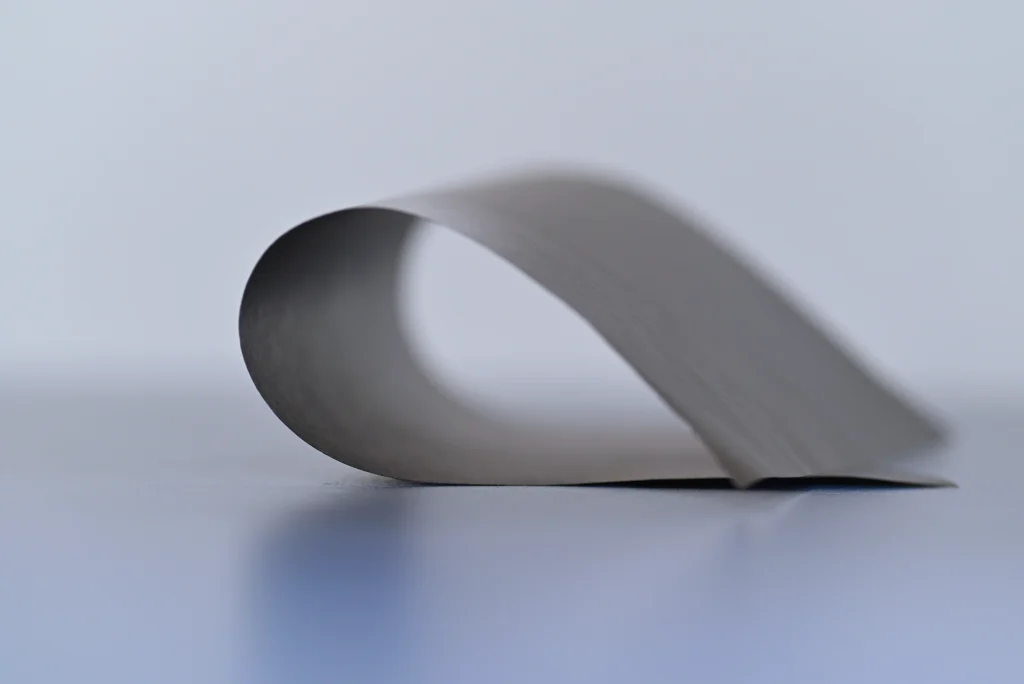

G6 is a new generation flexible full-field heater, developed from the G+Board project within Graphene Flagship, Europe’s most ambitious graphene research programme. This ultra-thin, flexible and resistant polymer coating is enriched with Nanesa‘s proprietary graphene, designed for high-performance applications.

G6 is an innovative alternative to traditional copper coils or carbon wire resistors. With a thickness of just a few hundred microns, it guarantees rapid and uniform heating thanks to its graphene-based electrical conductivity. This ensures even distribution of heat across the entire surface, as G6 is itself the heating element.

Technical characteristics and main advantages

Thanks to its extreme flexibility and customisation capabilities, the G6 graphene heater is ideal for a wide range of applications.

A high-performance solution compared to traditional systems, for various sectors of application

Made in Italy innovation with Nanesa graphene

G6 is designed and manufactured by Nanesa, an Italian company specialising in advanced graphene solutions. The company focuses on customisation, durability and easy integration into industrial processes or finished products. G6 is the ideal solution for those looking for a flexible, thin, powerful and versatile electrical resistance. Bring the efficiency of graphene to your application with G6.

We are ready to support you in developing flexible and innovative heating systems.

This line of nanocomposite materials, featuring an anisotropic structure, is produced using a cutting-edge spraying and lamination process. This process allows for the creation of thin, flexible, high-performance sheets. The basic formulation includes a reduced amount of polymeric binder and can be adjusted in terms of both chemical composition and percentage. This ensures maximum adaptability to different integration requirements. Its directional architecture and high compatibility with numerous polymeric substrates ensure that this technology is the ideal solution for integration into advanced structural composites, even in complex, high-performance applications.

Distinctive technical features

This technology stands out for a set of functional properties that make it ideal for applications in high-performance sectors:

Key benefits

Integration methods

Their unparalleled flexibility makes them the go-to choice for sectors such as aerospace, automotive, electronics, energy and defence, where a combination of lightness, functionality and reliability is paramount

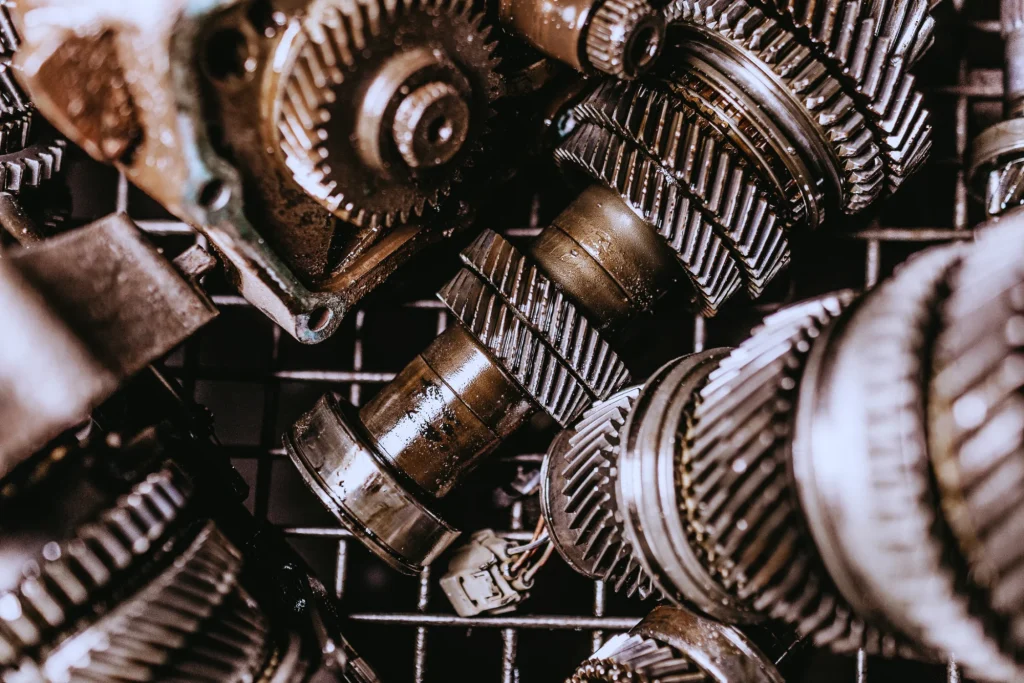

NANeGLIDE is an innovative metal-graphene composite coating developed and validated within the Graphene Flagship, one of Europe’s largest research projects dedicated to graphene and advanced materials.

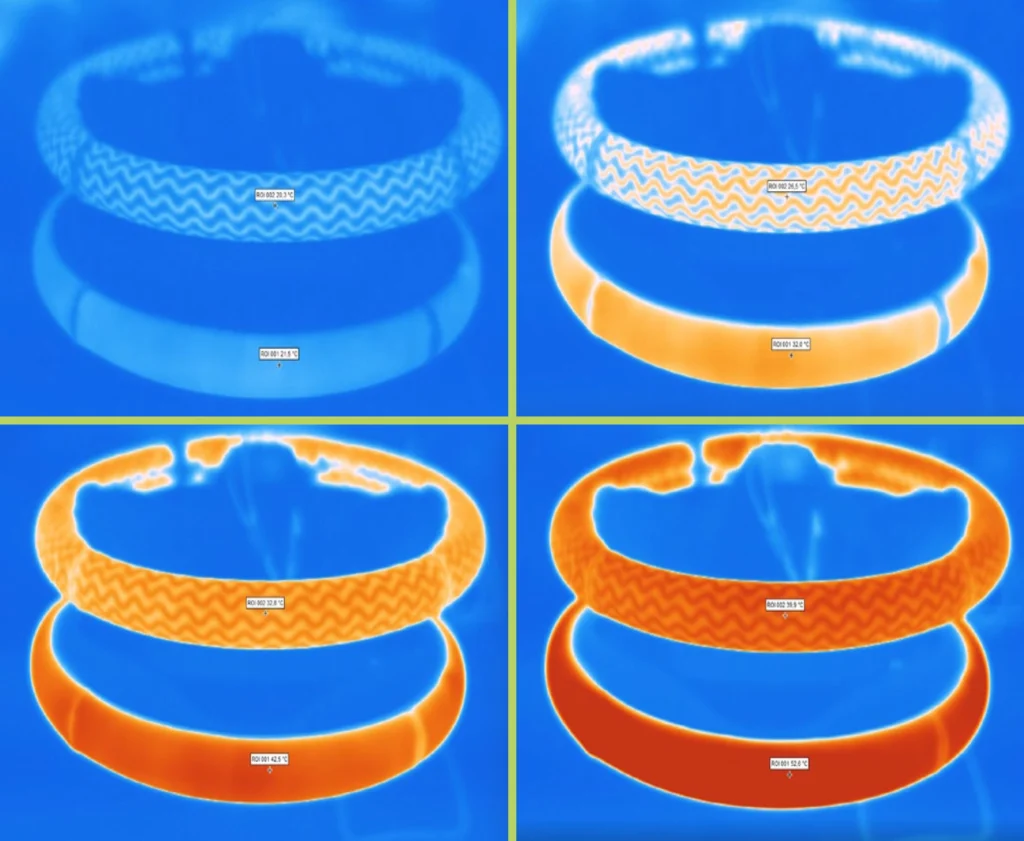

Designed for application to mechanical components subject to friction and lubricated with grease, this electrodeposited coating is the perfect solution. NANESA uses galvanic deposition technology to apply a self-lubricating coating in a solid state. This eliminates the need for periodic greasing and maintenance.

The advantages of NANeGLIDE coating

The application of NANeGLIDE offers numerous practical, economic and environmental benefits:

Coating technology and structure

The NANeGLIDE coating consists of a multi-layer structure obtained through galvanic deposition, in which a composite layer of metal and graphene guarantees excellent self-lubricating properties, wear resistance and protection against corrosion.

The coating has been developed in several variants, each specifically designed for components subjected to different levels of load and contact pressure. All ensure high performance and durability.

Reliability and guaranteed quality

The coating is manufactured in-house by NANESA, using a highly repeatable process that is rigorously monitored by an internal quality control protocol. This ensures maximum reliability, traceability and consistent performance over time.

By treating your mechanical components with NANeGLIDE, you can enhance their durability and reduce maintenance costs.

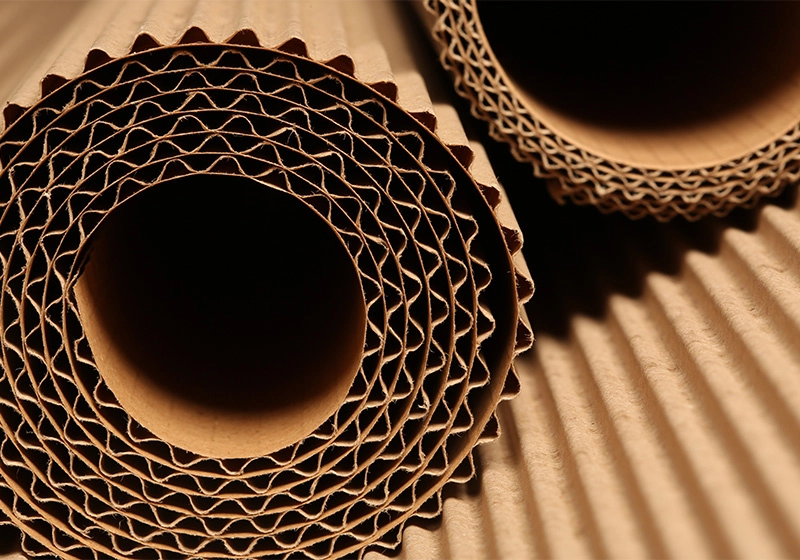

AD18Nan is an innovative additive developed by Nanesa‘s R&D department, specifically designed to improve the performance of natural starch-based glues (based on starch, casein and dextrins) used in the corrugated cardboard industry. This advanced additive is designed to assist companies in optimising production, reducing costs and enhancing the quality of the finished product.

AD18Nan’s unique formulation, incorporating Graphene Nanoplatelets (GNPs), delivers tangible results even at low dosages, eliminating the need for process parameter modifications.

Why choose AD18Nan for starch-based glues?

Industrial Tests – Concrete Results

In collaboration with our customers, full-scale tests were carried out on different types of waves (BC, C, EB) and with various papers. The results show an average performance increase of up to 25% compared to adhesives without additives.

Contact us to receive the technical data sheet or request a sample to test AD18Nan in your processes